every timber is unique and beautiful to the touch

Engineered for the harshest environments. Australia.

Equisol's unique formula protects your timber from mother nature's greatest forces. From the harshest tropical conditions to hail and snow, Equisol has you covered, giving you the best timber protection possible.

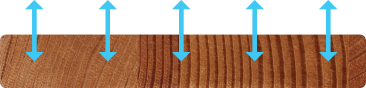

Technology that lets water get in and out again

Unique moisture control penetrant technology is the secret to how Equisol oil lets timber breathe.

Oil and water don't usually mix. This creates hassles in drying, especially as even dry timber can have a moisture content as high as 15%, and can leave uneven patches.

Moisture also reduces traditional timber oil's effectiveness in penetrating down and providing consistent protection. Equisol's technology allows our stabilising oil to penetrate the water barrier and push deep into the timber, drying much faster. It also lets moisture rise back out of the timber as it evaporates, minimising the damage of trapped water.

Stabilises Cell Structures

As water moves in and out of timber, it causes the cells to shrink and swell at uneven rates when they lose or gain moisture below their fibre saturation point.

These changes exert force on the cells' structural integrity as they move and push against each other, resulting in warping, twisting, cupping and finally splitting. Equisol provides dimensional stability at the cellular level by penetrating deeply and coating the cell walls, reducing moisture-related movement.

Mould and Algae Inhibitors

Equisol's environmentally-friendly linseed oil base is specially formulated with mould and algae inhibitors to help Equisol nourish and preserve timber. Enhanced UV absorbers also help control the effect of sunlight exposure.

The formulation increases rot resistance and helps stabilise timber's sugar content, which provides food for decay-causing moulds and fungi.

Nature can be a mother to your timber, don't let her

Timber is hygroscopic, meaning it absorbs water and sun in cycles of swelling and shrinking to balance with its surrounding environment. As moisture moves in and out, it attracts mould, bacteria, fungi and insect infestations if left untreated.

Most coatings attempt to keep water out, but water molecules are very small and eventually migrate through, creating a situation where water becomes trapped and failure is inevitable. The result is flaking, peeling coatings and damaged timber that must be heavily sanded back and possibly repaired before being re-coated.

If you've seen these signs, you have a problem.

UV Radiation

Prolonged UX exposure attacks film coatings and the underlying timber, breaking down the surface cells of the timber. The attached coating then flakes off.

Trapped Moisture

Water gets in through top coatings (and underneath if the underside is not treated correctly), leaving coatings brittle and cracking from trapped moisture, expansion and contraction.

Mould

Inferior decking oil or trapped moisture (especially in high humidity) allows mould spores to land, feed on the oil and grow, eventually turning your timber black.

Fungal Decay

Moisture enters through unprotected sawn ends, establishing fungal decay and attracting insects.

Rust and Holes

Nail and screw holes allow moisture in, accelerating mould and rust.

Splitting and Warping

Eventually the timber structure breaks down after continual shrinking and expanding with cycles of sun and water, requiring complete replacement.

For Complete Weather Control

Less mess, less work, longer life

| Can be applied on new timber immediately without weathering? | Yes | No | No | ||

| Can be applied on new timber without preparation? | Yes | No | No | ||

| Can be wet stacked for easy pre-oiling before construction? | Yes | No | No | ||

| Number of coats required on new timber? | Two | Three | Three | ||

| Single pack application needing only one product? | Yes | No | No | ||

| Can be applied on days that are hot, sunny, humid or cold? | Yes | No | No | ||

| Can be applied to damp timber? | Yes | No | No | ||

| No marks from dirt or leaves on deck during application? | Yes | No | No | ||

| No wet edge marks, even with minimum applying skill? | Yes | No | No | ||

| Average coverage rate (sqm/litre)? | 8-16 | 10-15 | 6-10 | ||

| Curing time in days? | Three | Seven | Seven | ||

| Does product ever blister, peel or crack? | No | Yes | Yes | ||

| Scratch resistant and easily repaired? | Yes | No | No | ||

| Reduces long term timber cupping, warping or splitting? | Yes | No | No | ||

| Number of coats required for re-coating maintenance? | One | Two | Two | ||

| No need to use paint stripper or heavy sanding for re-coat? | Yes | No | No | ||

| Recommended maintenance required (months)? | 6-12 | 12 | 3-6 | ||

| Re-coats build a long term accumulative benefit? | Yes | No | No |